e - Waste Management

Star Trace offers turnkey solutions for electronic waste recycling plants. We are one of the leading project suppliers for e-waste plants and we work closely with our customers to fulfill their specific needs for a customized packaged solution.

Electronic waste is the fastest-growing waste sector in the world and most people think of precious metals used in electronic equipment, they think of silver and gold. But even more costly metals, such as platinum, palladium, ruthenium, gold, silver and iridium are also important elements, primarily in producing corrosion free contacts. Because all these metals are both costly and scarce, recycling them is an important process in recovering these precious metals for reuse. With the purchase of a turnkey plant from us you can secure your share of this continually increasing future market.

Looking from a zero waste point of view, it is clear we need to set up a plant with the highest recycling/recovering ratio. Based on upcoming regulations, the products need to be treated in a way that enables the removal of contaminants in the e-waste. Therefore our philosophy is a multi step treatment where in the contaminants are removed from the process line.

Shredders

Primary ShreddersPrimary Shredders offered by us is designed to efficiently segregate most of the plastics as well as Ferrous/Non-Ferrous material. Featuring hydraulic motor driven drive, these are available in different production capacities as demanded by the clients.

Secondary ShreddersSecondary Shredders offered by us are designed to efficiently segregate and remove plastics & Ferrous/Non-Ferrous materials.

Features- With four wheels.

- High shred force.

- If the shredder blocked by big scrap metals, the shredder will stop.

- Efficiently processing high volumes of electronic waste.

- Recovering base metals such as aluminium, copper, zinc and steel.

- Recovering high value precious metals.

- Eliminating used electronic products and/or components from landfills.

- Providing secure destruction of customer's used equipment.

- Removing disposal responsibility of all product from the consumer while offering the manufacturer an opportunity to replace these products with new products.

Eddy Current Separators

Star Trace is a highly known and established manufacturer and supplier of eddy current separators, which are ready to be installed in your separation facility. This separator uses a highly powerful eddy current separators, conveyor belt, two variables discharge area and support frame. The optional vibratory feeder provides a consistent flow of material to the Eddy Current Separators. These top-class non-ferrous eddy current separators are highly reliable, durable, high performing and available at reasonable prices. Our eddy current separators is manufactured using the best quality raw materials to ensure satisfaction of customers.

These eddy current separator devices are perfect and effective work for removing non - ferrous metals from other products. Applications of eddy current separators are aluminum cans from municipal waste, aluminum flakes from shredded PET, brass and aluminum from foundry sands, and metals from shredded automobile/e-waste scrap. Other metals, such as lead can also be removed. For successful non-ferrous separation, a magnet should be installed prior to an eddy current separators.

Star Trace eddy current rtotor utilizes an alternate magnetic field for producing electrical currents in conductive metal. The electrical current produces its own magnetic field around an object, which opposes the magnetic field from the Eddy Current. This repulsion diverts the object from the product stream. Mass, conductivity and density influence the force and distance an object will repel.

Eddy Current Separation SystemEddy current separation system manufactured and supplied by Star Trace encompasses all the equipments above necessary to separate non - ferrous metals and add ferrous metal separation equipment. It is significant for removing ferrous metal prior to exposure to the eddy current separators. Strong magnetic field magnetizes and holds ferrous metal. The Ferrous Metal will heat up and could burn holes in belt and cause significant damage to the eddy current rotor.

Vibrating Unit

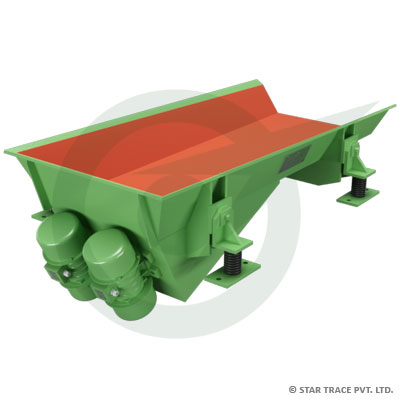

Vibratory Feeder

STAR TRACE Heavy-Duty Vibro Motor powered vibratory feeder is a high frequency reciprocating machine of heavy duty capable on conveying bulk material from storage to processing or between processes at a continuous controlled rate of flow.Thus vibrating feeder are used in processing industries for handling all types of materials such as hot, damp, lumps, dusty or abrasive for various function like flow of material from storage, proportioning and blending, packing, mixing, weighing, sprinkling, screening, scalping, crushing, washing, drying, heating, cooling, dusting, spreading, batching and etc.

STAR TRACE Vibratory Motors used in vibro feeder are totally enclosed 3 phase, squirrel cage induction motors with adjustable, eccentric weights mounted at both the ends of the shaft to set up vibrations during rotation. The design of shaft and the selection of bearings has been carefully done to withstand heavy radial loads. Two identical motors mounted parallel to each other on a right and left, which is free to move in all directions, will produce linear vibrations. When connected for conta – rotation so know this principle is adopted for handling large bulky material in large feeders.

This Vibrator Motor stator frame is fabricated in steel or cost in spheroidal graphetic Iron and the windings / connections are properly reinforced to with stand the heavy vibrating forces. Vibrator motors can be adopted for conveyors and feeders for handling large quantities of materials is moved by linear force along with conveyor. Usually vibrator motors are fixed at an angle between 30o to 45o to the plane of the conveyor. This gives the system both upward and forward motion and horizontal vibrations to the tray which ensures a free, smooth, uniform and volumetric flow to the material that is fully variable.

STAR TRACE Heavy-Duty Vibrating Feeders are available in a variety of trough size and shapes as per IS:8723 1978. The vibratory tray is heavily fabricated duly stiffened with angles wear resistance plate can also be provided in the tray for varying abrasive materials. Tray can be made to suit individuals requirement. This can be made dust tight too.

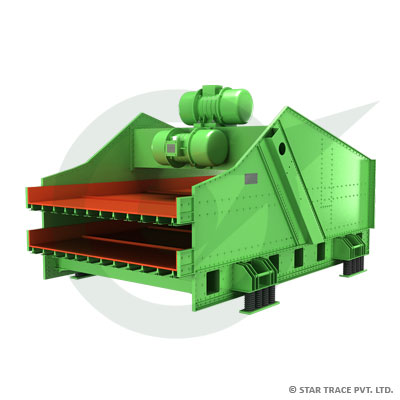

Horizontal Vibrating Screen

Whilst enjoying immense popularity for many years on small horizontal and inclined screens, STAR TRACE is the first company in the india to perfect this simple drive arrangement on large horizontal and inclined screens.This single development has resulted in tremendous advantages as far as reduced maintenance, compactness and simplicity are concerned. Besides the simplicity of the drive, many other features have been incorporated to provide a machine which is specifically designed for heavy duty applications, long life, and low operating and maintenance costs, at a competitive price.The standard range of screens is presented later in the brochure, and these are normally available on short delivery.

- No External drive, with vee-belts or cardan shafts.

- No Oilbath oscillators, with synchronising gears and oil leaks.

- Motor support stand, or overhead structure for motor support.

- Snubbers - the screen-mounted drive has eliminated the need for snubbers to reduce damage to vee-belts and external motors during the large oscillations that normally occur during stopping.

- Bearing failure is limited to the bearing itself. Particles from a failed bearing cannot circulate in an oilbath and cause possible damage to other bearings and synchronising gears.

- Campactness - screens can be positioned very closely with a minimum of space wastage.

- A vibrator motor needing reconditioning can easily be exchanged for a standby unit, with a minimum of downtime.

- Due to the absence of gears and vee-belts, the units use less power than conventional drives.

- The screens can be adapted by the factory to meet special requirements regarding plant layout, screen performance and environmental constraints.

- Screens are frequently manufactured in various grades of stainless steel for the chemical industry and protected by special painting systems for severe conditions in the mining/e-waste recycling industry.

- Specify your particular requirements, or enquire about the range of features, accessories, painting systems and materials of construction currently available.

Screen Separators

Star Trace Screen Separators is a unique particle size gradeable separator designed for greater capacity per metre square of screening area & over size material discharge with relatively much less percentage fines than other screening machines.

Major User Industries- e-waste recycling plants

- Food & Beverages

- Abrasive Industries

- Chemical

- Pulp & Paper

- Rubber Industry

- Ceramic

- Animal Feed

- Effluent & Waste

- water treatment

- Paint & Pigments

- Sand & Gravel

- Petroleum

- Sugar & syrup

The top weight on the motor shaft rotates in a plane close to the centre of the mass of assembly. Rotation of the top eccentric weight creates vibration in the horizontal plane which causes material to move across the screen cloth to periphery. Increasing the top eccentric mass, increases the horizontal throw, causing oversize material to discharge at a faster rate. The bottom eccentric weight rotates below the centre of mass, creating tilt on the screen, giving vibration in vertical & tangential planes. Increasing the vertical component of motion, which promotes turn over of material on the screen surface helping maximum quantity of undersize material to pass through the screen. The vertical motion also minimizes blinding of screen by near size particles. The tangential component of motion is controlled by the angle of lead given to bottom weights with relation to top weight. Variation in lead angle controlled the spiral pattern of material travel over the screen cloth. Speed & flow pattern of material travel over the screen cloth can be set by the operator for maximum throughout & screening efficiency for any screen able product.... wet or dry...coarse or fine… Heavy or light… hot or cold. Typical material passes rapidly through the screen during its travel to the periphery. The over size material get continuously discharged through a tangential outlet.

Incineration

It is a controlled and complete combustion process, in which the waste material is burned in specially designed incinerators at a high temperature (900o C - 1000o C).

Advantage of incineration of e-waste is the reduction of waste volume and the Utilization of the energy content of combustible materials. Some plants remove iron from the slag for recycling.

By incineration some environmentally hazardous organic substances are converted into less hazardous compounds.

Rotary Kiln IncinerationThe Rotary Kiln Incineration is a chemical reactor especially designed to burn solids, usually wastes that contaminate adsorbents (such as fuller's earth soaked with crude oil from an oil spill, or soil contaminated by liquids or solids in a landfill). Liquid wastes may also be treated either by direct feed to burners or in drums (plastic, fiber or steel).

Although rotary kilns are not specifically designed to burn gases, they are used for that purpose in chemical manufacturing plants where advantage can be taken of pollution control equipment associated with a rotary kiln burning other waste.

The incineration of waste materials in a rotary kiln is an extremely complex process involving physical movement of solids, liquids, and gases, in addition to chemical reactions.

Refining Unit

Overband Magnetic Separators

Supreme quality and flawless functioning are exhortations that best characterize the range of Overband Magnetic Separator we offer. Overband Magnetic Separator that we manufacture and export are high on demand by foundries, domestic waste recycling plants, cement industry, e-waste recycling plant, food industry, coal mines etc among others. Avail from us these Overband Magnetic Separators at most affordable prices.

Applications- Eliminating tramp metal from the products carried through:

- Belt

- Vibratory feeders

- Inclined planes

- Protection of machines like shredders, crushers and many more for removal of ferrous particles and purifying the products.

- Two U-section pieces are attached to the Magnet by fastening ears and supporting bearings of drums.

- Drums are provided with shafts mounted on removable hubs.

- All bearings offered with stakes to tighten the belt.

- Belt is driven through reduction gear coupled to geared motor / electric motor with vee- belts.

- Magnet is fabricated using high intensity strontium ferrite magnets and acclaimed for high magnetic power.

- Offered with non - magnetic stainless steel plate for covering the magnet poles.

- No requirement of electrical supply.

- Minimal maintenance.

- Five type of Separators redesigned for operation at a predetermined working gap over the conveyor: 100, 150, 200, 250 and 300mm.

Magnetic Drum Separator

Permanent Drum Type Magnetic Separator is most useful non electric separator for separating tramp iron from non magnetic material processed in bulk quantity for the purity of end products, recovery of metal having commercial value and protection of processing plant and machinery. These are widely used in all the processing industry for separation of iron contamination from mineral, chemicals, food, flour plastics, grains, sand, cement, fertilizers, abrasives, glass, slag, ores, rock, Refractory,e-waste and any other Products.

Size RangeThe permanent drum separators are available in standard drum diameters of 300mm, 400 mm. Drum width range from 300mm to 1200mm. Other sizes can be made as special to your requirement. The larger the diameter and width of the drum the greater is the volume of material which can be handled.

- Drum consists of high energy Rare Earth Neodymium Permanent Magnets.

- Strong & rugged construction. Automatic Separator of iron impurities.

- Completely enclosed design to avoid dusting and pollution.

The Permanent Magnetic drum consists of stationery Permanent Magnetic assembly having uniform and everlasting Magnetic field across the entire width of the drum, which is effective over approximately half the drum circumference. Drum shell made of non magnetic stainless steel revolves around the magnetic field. As the material feed evenly from the chute falls over the drum, Powerful-magnetic, field attracts and holds ferrous particles to the revolving shell. As the revolving shell carriers the iron particles through the stationery magnetic field, the non magnetic material falls freely from the shell while ferrous particles are firmly held till carried beyond divider and out of magnetic field. The strength of the Permanent Magnetic Drum is guaranteed to be grater than corresponding Electromagnetic Drum.

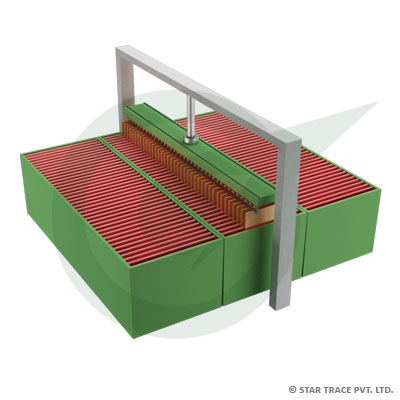

Magnetic Roll Separators

STAR TRACE was the first to introduce indigenous High Intensity, High Gradient Magnetic Roll Separator for use of dry material in Indian Market. It is capable of separating a wide variety of materials from different industries in an efficient and economical manner. It has operated successfully since 1993 in numerous production application in various industries. Star Trace uses high energy Rare Earth Neodymium Permanent Magnets assembled in a proprietary configuration to generate forces of magnetic attraction, which can be used for processing any material from ferromagnetic to weakly paramagnetic. The exceptionally high magnetic gradient achieved by the unique Star Trace design results in extremely large separation forces, exceeding those of any electromagnetic induced Roll Separators. Star Trace incorporates improved design features resulting from an ongoing product development philosophy combined with extensive operational experience.

A short special fabric conveyor belt envelopes the magnetic roll and a tensioning idle roll which was driven by a motor. A feeder discharges material on the belt on continuos controlled rate of flow at uniform layer thickness. The ferromagnetic and para magnetic particles add here to the belt while the non magnetic particles flow freely off the end of the conveyor. The division of para magnetic and non magnetic can be adjusted by using a splitter plate located below the belt. It can be configurated stacked in any no of passes to suit the user requirement.

APPLICATIONThe open design of the Star Trace allows both coarse and very weakly magnetic materials to be treated successfully. Proven dry process application include material from 75 microns up to 100 mm (4 inch) particle size, at through puts from 200 kgs to 60 TPH ( depending on size).

TYPICAL APPLICATION INCLUDEe-waste recycling plants, Andalusite and pyrophyllite beneficiation, diamond beneficiation, Chromite recovery, Magnesite beneficiation, Wollastonite beneficiation, metal value recovery from waste, Iron and manganese ore beneficiation, abrasive and refractory raw materials cleaning, Diatomaceous earth cleaning and kyanite cleaning, Glass raw materials cleaning, Slica Sand, Quartz, Feldspar, Dolomite etc. Bauxite cleaning, Ceramic raw materials cleaning, feldspar cleaning selective separation of garnet/ilmenite/rutile/zircon recovery, removal of ferro silicates from limestone, Magnesite , etc

Hammer Mill

Star Trace hammer mills are ideally suited to processing applications such as the fine crushing or grinding and drying of soft to medium-hard raw materials and e-waste recycled products. Star Trace hammer mills are renowned for their reliability, efficiency and are extremely versatile and adaptable to the most complex of processing demands.

Star Trace hammer mill can grind all kinds of materials of pellet feed, such as corn, sorghum, grain, legumes, broken cake pellet and others. Building in rotor, grind the raw material with no dead angle, finished products would be more even.

Operate door can be moved fully, it is easy to be operated.In-built sealed avoid dust spill out, keep the working environment tidy and clean.

It may carry on the ordinary grinding, also may carry on the thin grinding and the micro grinding. Thus it has been widely used in the e-waste grinding of the large and medium scale feed factory and so on.

ApplicationsExamples of the fields of applications of our hammer mills are operations in the raw materials processing, e-waste recycling and chemical industries.

The long list of materials processed includes limestone, fertilizer, lignite, dolomite, rock salt, electronic waste and metal shavings, to name just a few.

Depending on the intended use and the model of hammer mill selected, the achievable product size of the crushed material lies between 1 mm and 6mm, based on a feed size of 40 – 250 mm and a feed rate of up to 300 tons/hour.

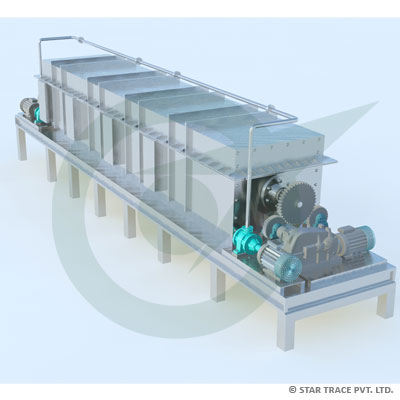

Shaking Table

Application of Shaking TableConcentrating Tables are designed to wet/Dry gravity-based separation of e-waste and other granular materials.

There are many applications where the concentrating table is of particular value and cannot be equaled for economical and efficient performance. They are effective in processing precious and base metal, rare metal and non-metallic minerals.

CONSTRUCTIONHead Motion

Examples of the fields of applications of our hammer mills are operations in the raw materials processing, e-waste recycling and chemical industries.

The decks are built of 16 mm zircon-reinforced fiberglass with fabricated steel frames at the bottom and are easy to clean, requiring little maintenance. The specific gravity of fiberglass made into decks is one third of that of steel, while its strength reaches as high as 70% that of steel. This fiberglass desks also has the characteristic of water- resistance and corrosion-resistance and can hold the shape unchangeable at ± 50o C.

BaseA choice of ordinary type, groove steel support or big channel steel support is available.

Air Separator

In e-waste recycle processing, controlled air is a perfect separation medium,both in terms of process technology and business solutions.Controlled air is one of the core technologies of Star Trace. It is versatile,offers greater flexibility than mechanical separation technologies and it guarantees high separation efficiency. By using air, materials can be separated based on both material density and shape. Star Trace, has optimized air technology for waste separation. The company is a recognized key player in its field.

The air separator is a combination of a recirculation fan, a separation unit (diagonal shifter, vertical shifter or zig-zag shifter) and a combi separator. It is the best separating solution based on density of the material at capacities up to 100 tonnes/hr. The low-maintenance Windshifter is a proprietary design of Star Trace. It offers effective separation and operational reliability, with a proven and long track record at customer plants worldwide.

The Windshifter is utilized for the separation and/or upgrading of the following Waste qualities.

- e-waste recycling process.

- Municipal Solid Waste. (MSW).

- Commercial and Industrial Waste (C&I).

- Construction and Demolition Waste (C&D).

- Compost Refinement section.

- Waste from Electric and Electronic Equipment (WEEE).

- Biomass/Wood recycling.

- Refuse Derived Fuel (RDF).

- Single Stream (DSD/PMD).

The Windshifter is utilized for the separation and/or upgrading of the following Waste qualities.

- Proven high operational reliability, i.e. increase of effective production time.

- High separation effi ciency – up to 99 wt.%.

- Gives control of the caloric value of the output.

- Removes interferants from input, thus protecting the granulators in RDF refi nement.

- Low maintenance and very few wearable parts, i.e. reduced downtime, low operational costs.

- Low dust emission.

Electrostatic Separator

The electrostatic separators are classified into two main types, such as electrodynamic separators or high tension roll separators and electrostatic plate and Screen separators. Both the separators work in similar ways, but the forces applied to the particles are different i.e. gravity and electrostatic attraction forces. In high tension rollers, the particles that subsequently travel on a drum are charged by a corona discharge. The conducting particles lose their charge to the drum and are removed from the drum with centripetal acceleration.The electrostatic plate separators work by passing a stream of particles past a charged anode. The conductors lose electrons to the plate and are pulled away from the other particles due to the induced attraction to the anode. These separators are used for particles between 75 and 250 micron and for efficient separation to occur, where the particles need to be dry, and have a close size distribution and uniform in shape. Of these considerations, one of the most important is the water content of the particles. This is important as a layer of moisture on the particles renders the non-conductors as conductors as the layer of the water is conductive.

Electrostatic plate separators are usually used for streams that have small conductors and coarse non-conductors. The high tension rollers are usually used for streams that have coarse conductors and fine non-conductors.

The plate separators used for separating mineral sands ie. zircon, rutile and ilmenite are separated from the silica gangue. The separation is performed in a number of stages with roughers, cleaners, scavengers and recleaners.

Applications- e-waste recycling plant.

- Beneficiation of ferrous, non -ferrous and rare metal ones.

- Recovery of metals from industrial wastes (electronic or electrical

- engineering scrap, cables etc.

- Recovery of dielectric materials (e. g. plastics) for recycling.

- Purification of metal and non -metal powders.

- Separation of industrial minerals (quarts, feldspar, mica etc.).

- Shape and size classification.

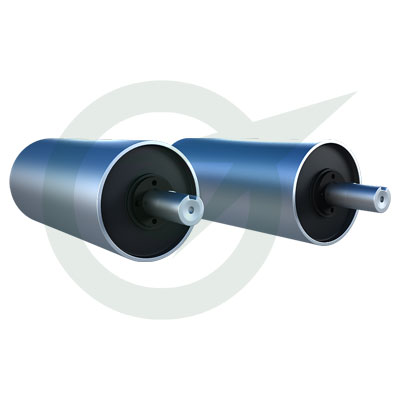

Permanent Magnetic Pulleys

Here how star trace heavy-duty magnetic pulleys remove tramp metal. Star trace magnetic separator pulleys are ideally used as head pulleys in belt continuous and automatic removal of tramp metal from material flow. As the tramp metal contaminated material comes within the pulley magnetic field, the ferrous tramp will be attracted and held to a belt until it reaches the underside. It will then pass separately out of the magnetic field and be discharged into a chute of bin. The cleaned, non-magnetic material is discharged normally over the pulley in a vertical drop.

The comprehensive STAR TRACE line of powerful permanent magnet separation pulleys meet the size and installation requirements of most conveyor systems applications. Installed as head pulleys in conveyor systems the STAR TRACE permanent magnet pulleys provide effective, full time automatic tramp metal removal.

STAR TRACE magnetic pulleys are provided in four different hub styles-extended hubs, flush hubs, recessed hubs and with no hubs. Pulley shafts are removable mild steel and are available with optional stainless steel shaft. Standard pulley sizes range from 4 different by 10 face width.

STAR TRACE pulleys are available with or without lagging and with crowned or flat faces. STAR TRACE pulleys provide many years of durability and extended service life.

Features- 304 Stainless steel faces.

- Removable mild Steel shaft.

- Four hub styles.

- Flat face.

- Keyway and set screws.

- Tapper Locks.

- Crowned face.

- Fixed shaft.

- Lagging.

- Stainless steel shaft.

Belt Conveyors

The conveyor belt can be categorized as basic belt, snake sandwich belt and long belt. According to kinds of drive, it can be divided into mechanical conveyor belt and electric conveyor belt. According to materials, it can be classified as rubber conveyor belt, nylon conveyor belt, polyester conveyor belt, EP conveyor belt, etc.

Our conveyor belt is a transmission component of the mining crushing machine. It can be used as e-waste recycling plant, mining conveyor belt and coal conveyor belt.

ClassificationAccording to kinds of drive, our conveyor belt can be divided into mechanical conveyor belt and electric conveyor belt. The former use planet-cycloid reducer and vee belt to convey goods. The latter is driven by motorized pulleys.

- The conveyor belt can be used independently, or used together with other conveying equipment.

- Its working temperature is in the range of -20 to 40. The temperature of delivered materials should be below 50.

- It features high transportation volume, simple structure, reliable performance and easy maintenance.

Our conveyor belt is extensively used to convey bulk materials or end products in e-waste recycling plant, mining, metallurgy, and coal industries.

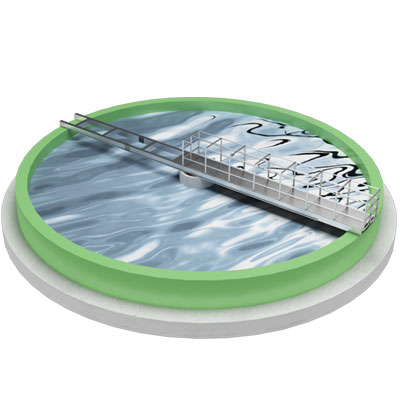

Electrowinnings

Electrowinning, also called electroextraction, is the electrodeposition of metals from their electronics scrap that have been put in solution or liquefied.

In electrowinning, a current is passed from an inert anode through a liquid leach solution containing the metal so that the metal is extracted as it is deposited in an electroplating process onto the cathode.

In electrorefining, the anodes consist of unrefined impure metal, and as the current passes through the acidic electrolyte the anodes are corroded into the solution so that the electroplating process deposits refined pure metal onto the cathodes.

The precious metal operations consist of the smelter, the copper-leaching and electro winning plant and the precious metals refinery. The operations are designed in such a way that raw materials, can enter the flow-sheet at the most optimal process step. The smelter separates precious metals in a copper bullion, from mostly all other metals, concentrated in a lead slag, further treated at the base metals operations. After leaching out the copper in the leaching and copper electro winning plant, the precious metals are collected in a residue that is further refined at the precious metals refinery. The precious metals refinery combines different methods recover precious metals (silver (Ag) and gold (Au)) and platinum group metals (platinum (Pt), palladium (Pd), rhodium (Rh), iridium and ruthenium).

STAR TRACE offer a complete electrowinning to provide reliable and trouble-free operation for the entire life cycle of the plant.

Leaching Process

Scrap printed circuit boards were selectively smelted at 1 200o C to produce a metallic alloy having three phases. These phases were identified as a lead-rich phase, a low tin content alpha bronze phase, and a high tin delta phase.

Electrochemical leaching method on this alloy were done in 1 mol/dm3 sulfuric acid or in 2 mol/dm3 hydrochloric acid (adjusted to an ionic strength of 3 mol/dm3). The lead rich phase was more strongly passivated in sulfate media, and in this medium the high tin content delta bronze was more resistant to corrosion than the lower tin alpha bronze phase.

In chloride medium the lead phase and both bronze phases corroded readily, but with current densities about an order of magnitude lower than in sulfate medium (static conditions) for the bronze phases. The high tin delta bronze phase was found to form a passivating layer in sulfate media. A similar layer was not seen in chloride medium.

The leaching method in sulfate medium also showed the existence of an alpha bronze phase of lower tin content in the centres of the alpha phase grains. This phase was quite resistant to leaching in sulfate medium.

STAR TRACE offer complete leaching process with highly cost-effective and environmental friendly process.