Incineration

It is a controlled and complete combustion process, in which the waste material is burned in specially designed incinerators at a high temperature (900o C - 1000o C).

Advantage of incineration of e-waste is the reduction of waste volume and the Utilization of the energy content of combustible materials. Some plants remove iron from the slag for recycling.

By incineration some environmentally hazardous organic substances are converted into less hazardous compounds.

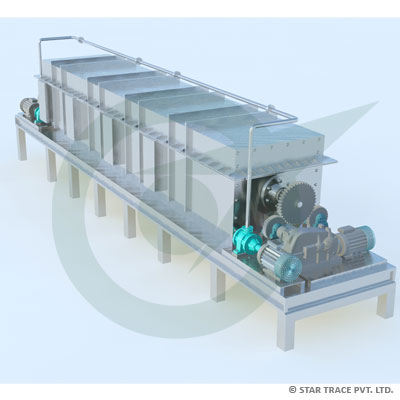

Rotary Kiln IncinerationThe Rotary Kiln Incineration is a chemical reactor especially designed to burn solids, usually wastes that contaminate adsorbents (such as fuller's earth soaked with crude oil from an oil spill, or soil contaminated by liquids or solids in a landfill). Liquid wastes may also be treated either by direct feed to burners or in drums (plastic, fiber or steel).

Although rotary kilns are not specifically designed to burn gases, they are used for that purpose in chemical manufacturing plants where advantage can be taken of pollution control equipment associated with a rotary kiln burning other waste.

The incineration of waste materials in a rotary kiln is an extremely complex process involving physical movement of solids, liquids, and gases, in addition to chemical reactions.